A milling machine removes unwanted material from the workpiece by rotating a cutting tool in or on the workpiece. The workpiece is usually made of metal but can be plastic or wood. The milling machines help in crafting workpieces in the desired shape, making grooves, creating slots, and also creating a smooth or rough finish in the workpiece.

There are both manually-operated milling machines and software-controlled CNC milling machines. The latest milling machines offer great precision ensuring great outcomes. The multi-axis milling machines are often equipped with CNC programming and can work in 3 or more axes, thereby operating on the workpiece from different angles, providing more accurate results. Let us discuss parts of milling machines and about 5 major types of milling machines and their operation.

Parts of Milling Machines:

The major parts of a milling machine are

Spindle: The spindle holds the cutting tool and rotates the cutting tool thereby removing material from the workpiece.

Worktable: The worktable holds the workpiece and it can be moved to position the workpiece relative to the cutting tool to achieve desired results.

Cutting tools: There are different tools for cutting such as end mills for making holes and cutting shapes, face mills for changing surfacing finish, ball mills for making curves and rounded edges, and more.

Types of Milling Machines:

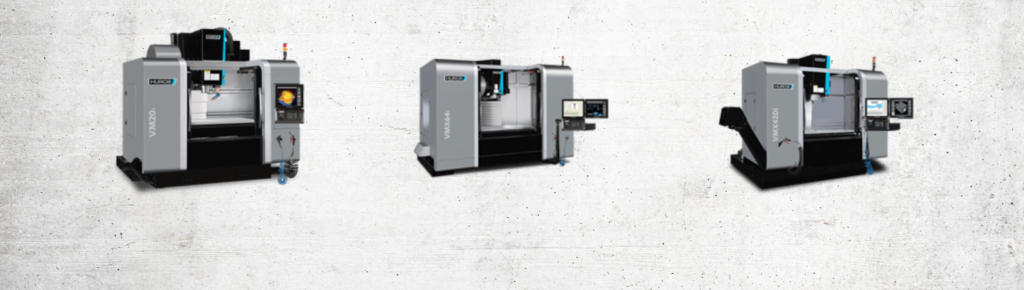

Vertical Milling Machines: In Vertical milling machines, the spindle is placed upright. It is mainly used for removing material vertically from the workpiece. The vertical milling machines are easy to operate. They utilize very little space for setting up as they are vertical. They offer very accurate chip removal thereby offering good quality output.

Horizontal Milling Machines: In horizontal milling machines, the spindle is positioned parallel to the work table. Horizontal milling machines are helpful for making slots, and grooves, and creating finishes. The horizontal milling machines can remove large unwanted portions and can handle thick workpieces.

Bed Milling Machines: In bed milling machines, the workbench is designed like a bed. This helps the machine to handle large workpieces. In bed milling machines, the cutting tool can be controlled to move in different directions. They can be used for both simple applications and complex applications.

CNC Milling Machines: CNC milling machines are milling machines operated with the help of computer programming. CNC milling machines helps in reducing manual workload and related errors. All machines can be CNC based such as vertical, horizontal, bed milling machines which are referred to as the types of CNC milling machines. Apart from accuracy they also help in saving time and cost. Since manual labor is not involved, they also help in improving safety.

Gantry Milling Machines: In Gantry milling machines, the workbench is large and the cutting tool can move back and forth in the gantry and also up and down. Therefore using the gantry and cutting tool, the workpiece can be carved comprehensively.

Conclusion:

These are the 5 types of milling machines used more commonly for major applications. Milling machines are used to manufacture components used in automobiles, aircraft, machines, mold making for manufacturing, engraving, and more.

It is essential to purchase high-quality milling machines for accurate results and long life. At Ray Mechatronics, we offer milling machines from top manufacturers across the world. We help to improve manufacturing processes with more than 25 years of industry experience.